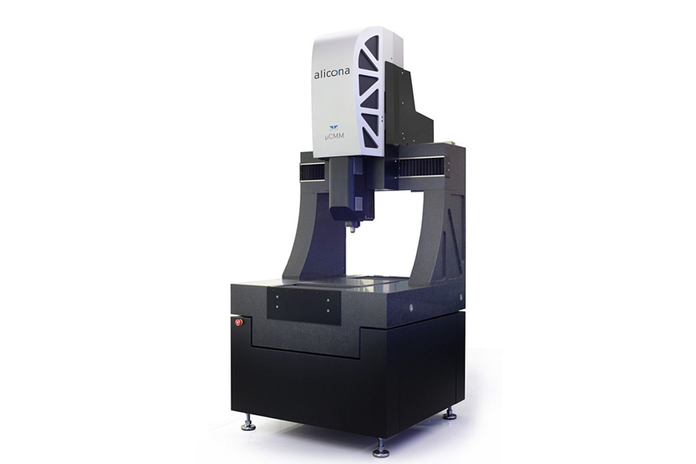

gAGEMAX cmm

Zeiss GageMax CMM

Our ZEISS GageMax Shop Floor CMM is integrated directly into our robotic production cell for un-manned 24/7 production monitoring and optimization.

Features:

Travel (X,Y,Z): 750 x 500 x 500mm

Acuracy: 1.9 + L/300 µm

Three-sided loading and operation

Temperature stability from +15 ºC to +40 ºC

Compact dimensions, large measuring space

Movable with a forklift

Ram made of temperature-stable carbon-fiber

Includes stylus rack with 4 slots

CMM Inspection Report

High volume production is handled in our main production

area. While not an ISO Class clean room, the temperature is held to a nominal temperature of 20.00°C +/- 1.5°C. The main feature of this area is our 4 machine GF System 3R robot cell feeding four 5-axis milling machines as well as our Zeiss GageMax shop floor CMM for in process inspection.

High Volume

Production area